AC/DC control systems are essential components in various industries, providing precise control and regulation of electrical power. These systems are crucial for managing the functions of different machines, ensuring they operate correctly and efficiently. From industrial plants to commercial buildings, AC/DC control systems play a vital role in maintaining smooth operations and preventing electrical issues.

Understanding how these control systems work can help optimize their use and improve overall safety. AC Control Systems, which stand for Alternating Current, and DC Control Systems, which stand for Direct Current, each have unique characteristics and applications. By learning the differences between AC and DC systems, we can better choose the right type for specific needs.

Additionally, keeping AC/DC control systems well-maintained is vital for their longevity and performance. Regular checks and proper care can prevent unexpected breakdowns and costly repairs.

Understanding AC/DC Control Systems

AC/DC control systems are indispensable in managing the flow of electricity in various applications. AC, or Alternating Current, systems are characterized by the current changing direction periodically, making them suitable for transmitting electricity over long distances. This characteristic makes AC systems prevalent in residential and commercial buildings. They are widely used for powering household appliances, lighting systems, and other electrical devices.

On the other hand, DC, or Direct Current, systems maintain a constant direction of current flow, making them ideal for applications requiring stable and consistent voltage. DC systems are commonly found in battery-operated devices, computers, and certain industrial equipment. Understanding which type of control system to use depends on the specific requirements of the operation, such as the need for stability, distance of power transmission, and the nature of the electrical load.

Both AC and DC control systems are essential, and their usage often complements each other. For example, many electronic devices convert AC from the power grid into DC for internal use. Recognizing the differences and advantages of each type of system helps in selecting the right control system for your needs and ensures efficient and safe operation.

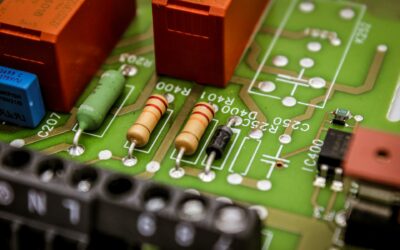

Key Components of AC/DC Control Systems

AC/DC control systems consist of several key components that work together to manage electrical power effectively. Understanding these components helps in troubleshooting and maintaining the systems.

- Transformers: In AC systems, transformers play a crucial role in changing voltage levels. They step up the voltage for long-distance transmission and step it down for safe usage in homes and businesses. This ensures efficient power distribution with minimal losses.

- Rectifiers: Rectifiers convert AC to DC, making them essential in systems where DC power is required. They simply allow current to flow in one direction, ensuring a steady supply of direct current.

- Inverters: Inverters perform the opposite function of rectifiers by converting DC back into AC. They are vital in applications like uninterruptible power supplies (UPS) and solar power systems where stored DC needs to be converted to AC.

- Switches and Relays: These components control the flow of electricity within the system. Switches manually open or close circuits, while relays automate this process, providing protection and control by responding to changes in the electrical circuit.

- Circuit Breakers: Circuit breakers protect the system from overloads or short circuits by interrupting the flow of electricity when an excessive current is detected. This prevents electrical fires and damage to the system.

- Wiring and Cables: Proper wiring and cables are essential for connecting all components and ensuring reliable power distribution. High-quality materials and correct installation practices help prevent electrical faults and ensure safety.

Each of these components plays a specific role in the efficient operation of AC/DC control systems. By understanding how they work together, we can better manage and maintain these systems for optimal performance.

Applications and Benefits in Various Industries

AC/DC control systems are used across a wide range of industries due to their adaptability and efficiency. In industrial environments, these systems control machinery like conveyor belts, robotic arms, and production lines. By providing precise control over the speed and function of these machines, AC/DC systems help improve productivity and ensure consistency in manufacturing processes.

In the commercial sector, AC/DC control systems are vital for operating HVAC units, lighting systems, and security alarms. These systems regulate power to ensure that equipment runs efficiently and safely. Using AC/DC control systems in these settings can lead to significant energy savings and enhanced operational reliability. The ability to fine-tune power delivery according to specific needs makes these systems indispensable in various industry applications.

Maintenance Tips for Optimal Performance

Maintaining your AC/DC control systems is crucial for ensuring their long-term performance and reliability. Start by conducting periodic inspections to check for any signs of wear or damage. Inspect wiring, connectors, and components for corrosion or loose connections, which can cause malfunctions. Keep the control panels clean and free of dust, as debris can interfere with the system’s performance and lead to overheating.

Regularly test the system to ensure all components are functioning correctly. Use diagnostic tools to monitor voltage levels and detect any irregularities. Keep a record of all maintenance activities, including the dates and nature of inspections and repairs. Update firmware and software for any digitally controlled components to benefit from the latest performance enhancements and security features.

Routine maintenance not only prolongs the life of your AC/DC control systems but also enhances their efficiency and safety. By staying proactive in system upkeep, you can minimize downtime and avoid costly repairs, ensuring that your operations run smoothly.

Conclusion

Understanding and maintaining AC/DC control systems is essential for maximizing their benefits across various applications. Whether in industrial, commercial, or residential settings, these systems offer precise control and enhanced operational efficiency. Regular inspections, preventative maintenance, and timely upgrades all contribute to the smooth and efficient running of these systems. By following best practices in system upkeep, you can ensure their longevity and optimal performance.

At Stalker Electric, we specialize in the installation and maintenance of AC/DC control systems. Our expertise ensures that your system operates safely and efficiently. If you need professional assistance with your AC/DC control systems, contact our experienced electrician today to schedule an inspection or consultation. Your electrical system’s efficiency and reliability are our top priorities.

0 Comments