Understanding how industrial electrical control systems work can be simple. These systems are used to manage and operate machinery and processes in factories and other industrial settings. They play a vital role in ensuring everything runs smoothly and safely.

These systems include components like sensors, relays, and controllers that work together to monitor and control industrial equipment. They help increase efficiency and reduce the risk of accidents by automatically handling complex tasks and operations.

In the following sections, we will explore the essential parts of industrial electrical control systems, their common uses in various industries, and tips for keeping them in good working order. This will help you get a better grasp of these crucial systems and their importance.

What Are Industrial Electrical Control Systems?

Industrial electrical control systems are crucial for managing and automating processes in factories and other industrial settings. These systems help regulate electrical equipment, ensuring everything operates smoothly and safely. By monitoring and controlling machinery, they help improve efficiency and reduce the likelihood of errors.

These systems can be simple or complex, depending on the needs of the operation. They might control everything from a single piece of equipment to entire production lines. Automation through these systems allows for better consistency and can enhance productivity. Overall, they play an essential role in industrial operations by managing electric power, ensuring safety, and boosting efficiency.

Key Components of an Industrial Electrical Control System

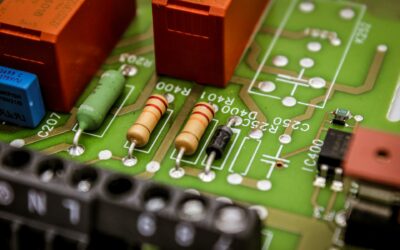

Several key components make up an industrial electrical control system. First, there are controllers, which manage the system and send commands to various parts. Programmable logic controllers (PLCs) are often used for this purpose because they can be easily programmed to meet changing needs.

Next, sensors collect data from the environment, such as temperature or pressure. This data is sent to the controllers, which make decisions based on the information. Other important parts include actuators, which carry out commands from the controllers by moving or controlling mechanisms.

Safety devices are also crucial. These include circuit breakers and fuses that protect the system from electrical faults. Proper wiring and connections ensure that all these components work together effectively. Understanding these parts helps in troubleshooting and maintaining the system efficiently.

Common Applications of Industrial Electrical Control Systems

Industrial electrical control systems have a wide range of applications. In manufacturing plants, they control machinery on production lines, ensuring each step is completed accurately. This helps maintain consistency and quality in the products being made. Additionally, these systems can automate repetitive tasks, which increases efficiency and reduces human error.

In other industries like oil and gas, control systems manage the complex processes involved in extraction and refinement. They monitor critical parameters such as pressure and temperature to ensure safe and efficient operations. These systems are also used in water treatment plants to control pumps, valves, and other equipment. This helps ensure that clean water is available and wastewater is treated properly.

Best Practices for Maintaining Industrial Electrical Control Systems

Regular maintenance is key to keeping industrial electrical control systems running efficiently. First, it’s important to conduct routine inspections to check for any signs of wear or damage. This includes examining wiring, connections, and the condition of components like controllers and sensors. Catching potential issues early can prevent costly breakdowns.

Keeping the system clean is also essential. Dust and debris can interfere with the functioning of components. Use appropriate cleaning methods and tools to ensure everything is free of contaminants. Additionally, updating software and firmware is important to benefit from the latest improvements and security features. Documenting all maintenance activities helps in tracking performance and identifying recurring issues.

Final Thoughts

Industrial electrical control systems play a vital role in various industries by managing and automating processes efficiently. They consist of key components like controllers, sensors, and actuators that work together to ensure smooth operations. Understanding their common applications, such as in manufacturing and water treatment, highlights their importance in maintaining quality and safety.

Maintaining these systems through regular inspections, cleaning, and updates is crucial for their longevity and effectiveness. By following best practices, we can ensure these systems continue to operate reliably, preventing costly downtime and improving overall productivity.

If you want to ensure your industrial electrical systems are maintained and installed correctly, contact our electrical contractors at Stalker Electric. We have the expertise to help you get the most out of your systems, keeping your operations running smoothly and safely.

0 Comments